Expertise for Lumen Beings: White light

Expertise for Lumen Beings: Lighting specialist Herbert Bernstädt now offers everything you need in all areas of lighting and spotlight technology. In the first edition of the series, the experienced lighting expert and development engineer deals with what is probably the most important light colour of all: white light.

White light – what it’s for

In addition to performance, stage lights or fresnel lens spotlights (fresnels for short) are selected primarily on the basis of their colour temperature. If nothing is specified, a halogen light source with a colour temperature of 3200K is assumed. Television studios also use artificial light. Artificial light because, unlike natural light, it is artificially generated with electricity. The term daylight, on the other hand, refers to discharge lamps as a light source that can produce colour temperatures of 5600K similar to daylight. A fresnel with halogen lamps cannot simply be equipped with a discharge lamp. The design differences that have to be implemented with the use of the discharge lamp are far too great, such as UV protection or protection against several thousand volt ignition voltage. With LEDs as a light source, the choice is extended by three principles.

LED = Three white light principles

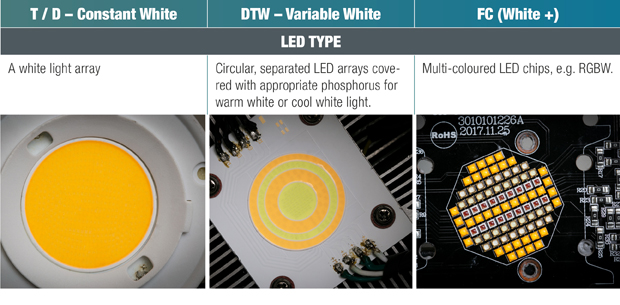

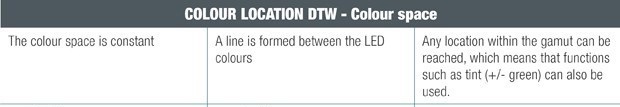

Just as you don’t convert a halogen fresnel into a discharge fresnel, you also have to decide in advance on one of the three types of white light for LEDs. This is because each principle requires the appropriate LED driver, which is not done by simply replacing the LED board. We distinguish between three systems:

- Constant white with a driver channel that only controls one type of white light LED.

- Variable white with two driver circuits that control two different white light colour temperatures.

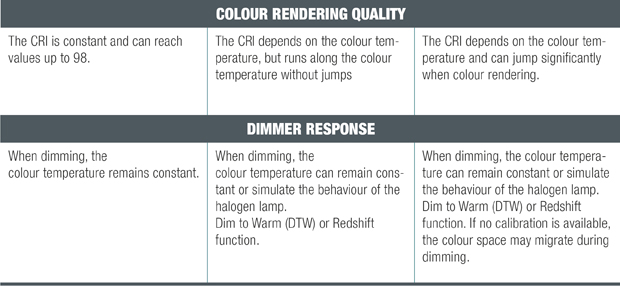

- And Full Colour, where the white light is generated from the sum of different LED colours. The table below shows the main differences between the three principles.

T or D constant white

Highest light intensity is guaranteed when a fixed colour temperature is chosen. This makes sense because every available LED chip contributes to the light intensity with full power. Light colours of 3200K or 5600K are generally available for artificial light or daylight.

In some cases, however, 3000K is also used, although the difference to the 3200K is only slight. 3000K burners were also often used for halogen lights, as they had 2,000 hours of average service life (mLd) as long-life types, instead of the normal 200h mLd for 3200K. An ACL 3400K burner can only provide 20 h mLd.

When white-light LED chips age, the colour temperature drifts hardly noticeably into the colder light colour because the phosphorus degenerates faster than the silicon crystal of the LED. The loss of brightness over the years under normal use can usually only be seen in a direct AB comparison. The distance to the irradiated object usually has a much greater influence than the age-related loss of brightness of the LED, provided it is operated in appropriate, not too hot parameters. However, if you still want to replace the LED array, Cameo spotlights can be quickly and easily replaced with screw and plug connectors.

It depends on the application as to whether it is advantageous that the colour temperature remains constant when dimmed. When a camera comes into play, you’ll always want to keep the colour temperature constant. If you want to create a warmer light colour with dimming, just like in theatre, a spotlight from the DTW series would be better.

Typical example:

F-Series: T for Tungsten (3200K) and D for Daylight (5600K)

DTW – Variable White

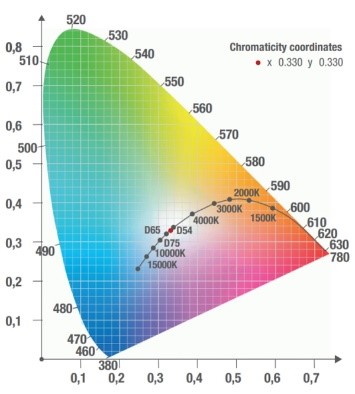

If you are unsure whether you want to illuminate with daylight or artificial light, variable white light fresnels are a good choice. Here, two LED types, a warm white LED and a cold white LED, are dimmed to one another. As a result, you can glide from one LED colour temperature to another almost seamlessly. However, at the main colour temperatures of warm white or cool white, about half of the LEDs remain dark. It depends on the control system or the power and thermal design as to whether the brightness increases or remains constant when fading the light colour in the “middle” – when both LED colours are controlled. This is also where the worst colour rendering index (CRI) is to be expected, as variable white creates a line between the LED colours. If the LED colours lie on the Planckian curve, which is naturally the destination of a white light LED, then the longest distance to the Planckian curve is in the middle. In fact, we no longer refer to LEDs as the colour temperature (CT – Colour Temperature), as this only affects heat lamps, i.e. halogen lamps. With LEDs, we are talking about CCT (Correlated Colour Temperature), which is equivalent to the near colour temperature.

If the colour temperature can already be changed, it makes sense to simulate the dimming behaviour of halogen burners (DTW Dim to Warm). This is usually done by using amber-coloured LEDs to add the reddish touch when dimming down. As a colour for gliding, amber is much more favourable to the Planckian curve than a red LED, although this function is also known as red shift. However, this is due to the red cast that the camera image receives when the halogen burner is dimmed down. With the P ST DTW, you can even switch the response time and the red shift function on and off via DMX. This makes it possible to conjure up a real blackout and to follow up the fading out of the tungsten thread, even if you have programmed your own times for fading out and deactivated the response time for the quick blackout. But more about that on DTW.

Typical example:

CL 200 G2 with a 3200K and a 7800K LED – There is no DTW here.

P ST DTW with two white light LED colours, 6800K, 2800K and Amber.

ZENIT P200 DTW with a 3100K and an Amber LED – there is no cold colour temperature available here, but there is a DTW function.

FC – Full-Colour – White+

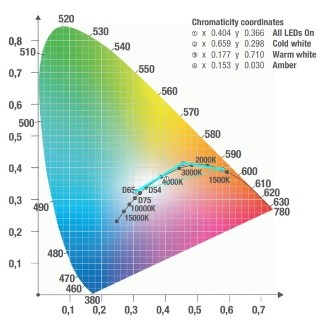

You can mix white light with yellow and blue, but it looks unattractive. The more colours added and the broader the spectra per colour, the better the mixed white is. Thanks to the mixing ratio, each colour space can be reached within the covered gamut. This means that the Full-Colour LED is not only able to reproduce saturated colours, but also white light at the desired colour temperature. If the control allows it, halogen lamp simulation (DTW) or shifting to green or magenta (tint) is also possible. This colour flexibility is purchased with a lower brightness.

In contrast to the white light engines described above, the aging of the LEDs in full-colour systems has a significant influence. Because if you can’t see the 1% difference in brightness with a white light chip, you will immediately see a different mixed colour when mixing colours. One solution is the calibration of colours, as is the case with our Cameo lamps from the professional segment. Here, the user can choose whether they want to perform the calibration themselves (user calibration), not to use calibration (RAW), or calibrate using a special control chip with a sophisticated algorithm of aging and dimming behaviour, as well as optimising the Planckian curve, brightness, saturation and much more. We call this “factory calibration”. This means that the colour space remains constant even when dimming down a mixed colour.

Another problem with multi-coloured light sources is the clean mixing of the colours in the spotlight so that a homogeneously mixed colour appears when looking at the spotlight. Of course, the light field should also be homogeneous and not form any colour edges. Multi-shadows on the barn doors or after objects are also not desirable. This is ensured by special optics in the F series, which we will discuss elsewhere.

If all the colours are available to you, it is often time-consuming to get exactly the colour you want from the device. Setting the white dot using red, green and blue alone is a big job, because if you pull all three basic colours to 100%, you are usually somewhere in the colour triangle, but not at zero. That’s why Cameo greatly values fast operation. First, you decide how you want to retrieve colour or white light from the lamp. With the first press of a button, the CCT light suggests white light or HSI, direct LED and gel for the different types of colour adjustment. If you want to use white light, press CCT and you just have to set your desired white light colour temperature. You can also conveniently adjust the magenta or green shift (tint) for white balance during camera operation. With HSI (Hue colour, saturation and intensity), three rotary encoders also allow direct access to the parameters to be set without you needing to navigate around any menus. The only faster way is to call up one of the more than 44 standard colour foils as a preset or a self-set colour as one of 8 user colours. Of course, a running light (play loop) can be set via the User Colours, meaning that, for example, a lamp standing in front of the window can also simulate a police blue light – without a stand.

Typical example:

F2 FC PO with colour calibration and DTW and the light is completely free of colour shadow.

Easiest to use, each with an endless encoder for brightness, colour temperature and tint.

View

In the next series, we will look at the LED lamp in combination with the fresnel lens and the barn doors.

Glossary:

CT- Colour Temperature – colour temperature on the Planckian line for thermal radiators

CCT – Correlated Colour Temperature – colour temperature corresponding to the Planckian lines

CRI – Colour Return Index – how well colours are perceived under light

DTW – Dim-to-warm – colour temperature change simulation corresponding to a halogen lamp

Red Shift.

Artificial light – halogen light corresponding to a colour temperature of approx. 3200K

Daylight – natural daylight is therefore similar to a colour temperature of approx. 5600K