Comparison of light sources: LED, laser, and discharge lamp

LED, laser, or discharge lamp? How do the properties of the light sources differ and for which lights are these light sources particularly suitable?

Before the time of LEDs, there were halogen lamps and discharge lamps. Making the choice between them was quite easy. Static conventional lights used halogen lamps for a colour temperature of 3200 K, thus for warm white or artificial light. Discharge lamps were used for a colour temperature of around 6500 K, namely for cold white or daylight. Of course, light conversion films could also be applied, but with a significant loss in light. With a few exceptions, halogen lamps were not suitable for moving lights due to the high proportion heat generated by the lamps. Energy-saving regulatory requirements then put an end to the halogen lamp. LEDs, special discharge lamps, and laser phosphor light sources are the only options still allowed to be installed in lights today. In the following, we’d like to clarify why discharge lamps are still being used alongside LEDs or even why technologically sophisticated laser phosphor lamps are being utilised.

The LED – the all-rounder

LEDs have some unbeatable advantages over discharge lamps: they are immediately bright upon activation and provide the desired quality of light. Plus they are also very easy to dim thanks to pulse-width modulation. An LED lamp can also be switched off instantly. LEDs have a very long service life of around 25,000 hours, which is just about the same as the lifespan of a fixture used under normal conditions. They are not likely to suddenly fail; LEDs usually just become dimmer over time. The LED can be cooled with a heat pipe leading away from the LED board. An efficient cooling system can thus be set up using heat conduction systems such as heat pipes. Depending on the LED type or combinations used, the quality of light can be very high. A very wide colour gamut that covers nearly all bases is also possible depending on the LEDs selected. RGBAL multicolour LED arrays, for example, ensure a large colour space (gamut), while the highest colour rendering qualities for warm white can be achieved using white light LED arrays. Depending on the LED system, colour stability can also be guaranteed across several devices with one calibration. If we need to increase the brightness, we simply join several LEDs together. But here’s the catch with this type of fixture: beam lights are intended to emit a very narrow beam of light. To achieve a good projection or narrow light beam, it’s beneficial if the light source is as compact as possible, which means emitting light as point-like as possible. The higher the light output of the LED system, the larger the array, which makes it more difficult to create a narrow point of light.

1400W LED array OPUS® X4

Left: honeycomb and lens for a homogeneous light surface.

Centre: converging lenses for the individual LED chips.

Right: LED chips create an array with a diameter of approx. 5 cm

The narrowest light beam achievable with the OPUS® X4 is 5.5°.

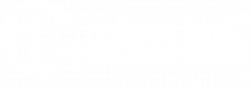

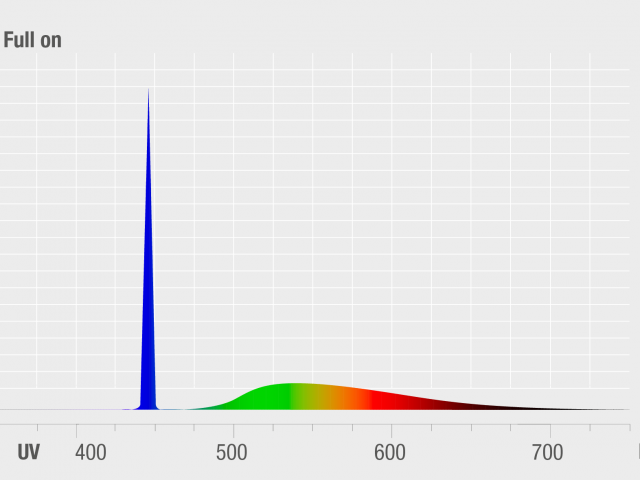

Spectrum of a white light LED optimised for brightness.

Maximum brightness at the detriment of colour rendering.

The discharge lamp – the projection talent

An example of a lamp with a very small light source and high radiance is the UHP lamp. Its discharge bulb is extremely small and has a very high operating pressure. That is why it is called the UHP lamp, which stands for ultra-high-pressure, but is often also referred to as ultra-high-performance. The discharge bulb is usually already optimally aligned in a reflector. This type of lamp was developed specifically for video projectors, where very good projection properties and high brightness with a small point of light are also crucial. A discharge lamp requires a burn-in time of several minutes until all chemical processes are in a stable state and the brightness and colour spectrum are therefore stable.

Discharge lamps are dim-resistant and must be dimmed mechanically in the lower setting range at the latest, otherwise the arc will break. As a discharge lamp, the UHP lamp also contains mercury. If the lamp bursts, which is not uncommon at the end of its service life, this environmentally hazardous heavy metal can leak. For this reason, a lamp like this should always be handled with care and only disposed of as hazardous waste! The service life is approximately 2,500 hours until total failure. As such, it should be possible to replace the light source. A high ignition voltage is also required to ignite a discharge lamp. This places a huge load on the system. That’s why it is also advisable to keep the lamp running for about two hours without switching it off. In terms of energy, the discharge lamp always operates at maximum capacity, even if it is dimmed all the way down. The LED has a clear advantage here, as it consumes less energy when dimmed. The light source itself must be cooled with air, and the light fixture must not contaminated by the flow of air at the same time. The discharge lamp should be cooled down gently during deactivation. You should avoid switching it off immediately (instant off). A discharge lamp’s colour spectrum has very strong blue and green colours, but weak red hues. The discharge lamp has a hard time producing warm white colour and has to be compensated with CTO filters with a corresponding loss of light. The colour rendering index is also not very high. High CRI filters, which are capable of adding a few CRI points but lead to a loss of brightness, are often used here too. The gamut (colour space) available to a discharge lamp is relatively small and is usually in the sRGB range.

UHP light source OTOS® B5’s Signify MSD Silver 480 W.

The arc measures just a few millimetres.

The narrowest light beam achievable with the OTOS® B5 is 1°.

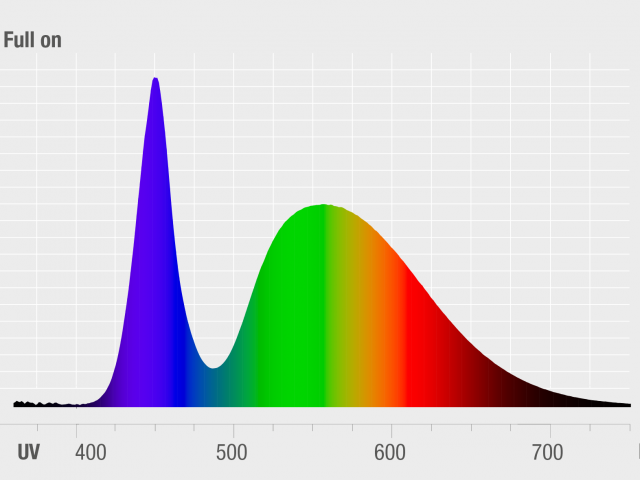

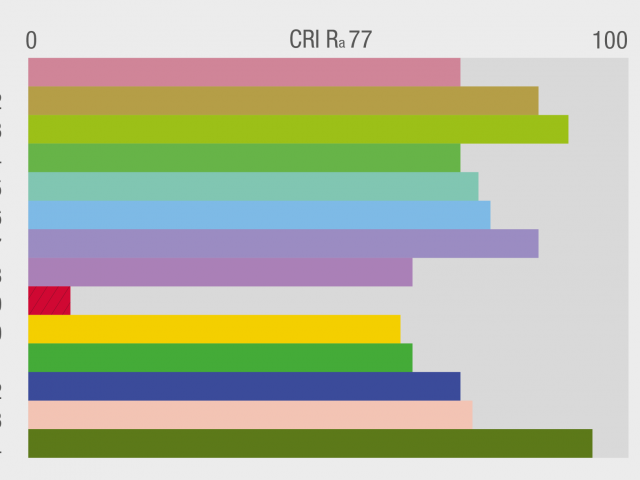

The discharge lamp is weak in the red range.

The CRI is 77.9, and the red range is even shown in negative.

The laser phosphor source – for “peak” values

An alternative for the UHP lamp is a laser phosphor engine. It was also developed primarily for use in video projectors. However, the laser phosphor engine’s design and technical complexity are considerably higher, and we’d like to give you a brief introduction here.

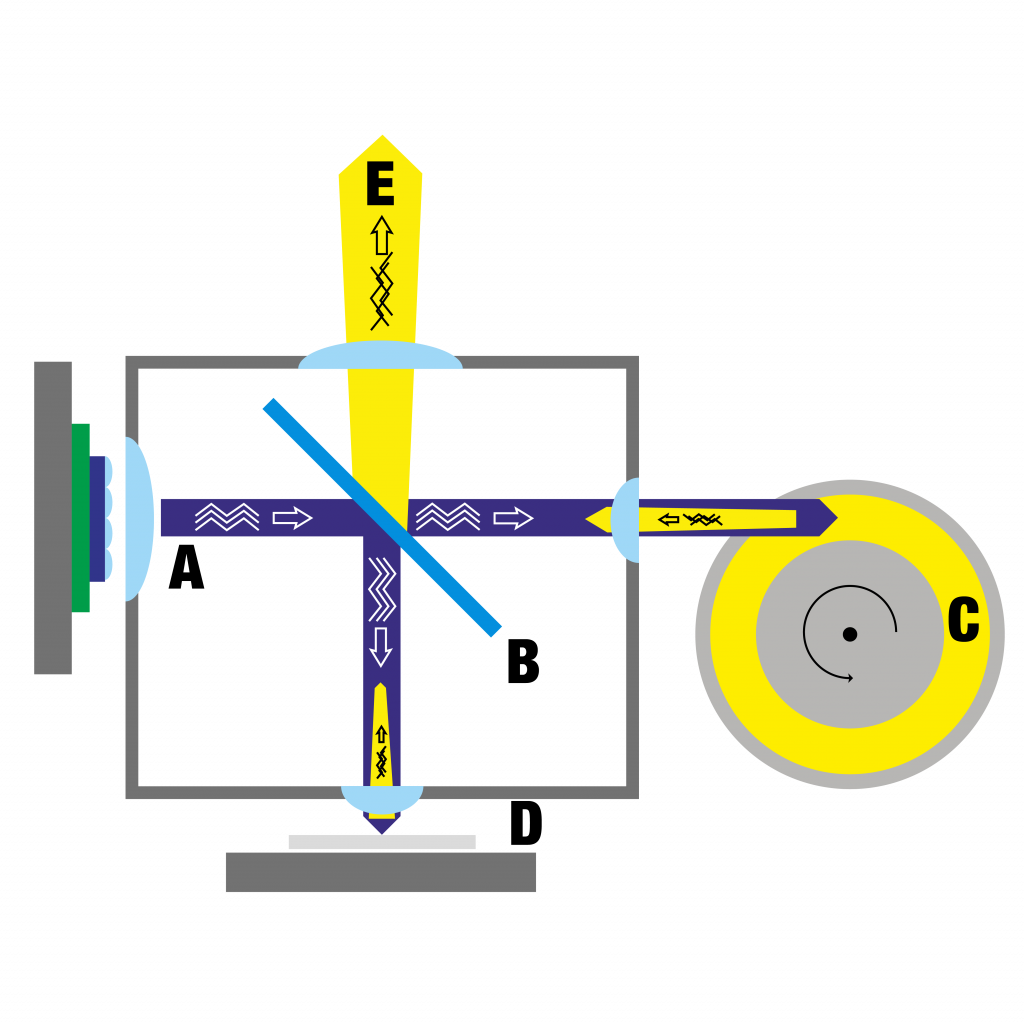

A: LED blue light laser array’s coherent light

B: Semi-transparent mirror for blue light

C: Rotating phosphor plate

D: Reflective layer of barium sulphate

E: Light output of incoherent light

A LED blue light laser array (marked with letter A in the diagram) emits coherent blue light towards a rotating phosphor plate (letter C), which is positioned opposite the LED blue light laser array. On its way there, the coherent light passes through a semi-transparent, coated mirror glass. Due to the 45° arrangement of the glass, some of the radiation is deflected onto a reflective layer (letter D), but we’ll delve into this in greater detail later. The phosphor layer is excited by the blue laser light and emits or reflects back incoherent light colours, such as green, yellow, and red. The glass arranged at 45° is now responsible for redirecting the incoherent light reflected by the phosphor layer to the light output (letter E) leading out of the laser phosphor module. Now let’s get back to the laser light deflected by 90°, which strikes a reflective layer of barium sulphate. Barium sulphate’s high efficiency and diffuse reflection makes it ideally suited for this task. The reflected blue light is now added to the phosphor plate’s incoherent light when it passes straight through the semi-transparent glass (letter E). If you look at the direction of the beam of the coherent light, you can tell that the selected arrangement means that no coherent light can leave the module, but only incoherent light due to the diffuse reflection.

ORON® H2’s 260 W phosphor laser engine, unscrewed.

Left: LED blue light laser array’s coherent light

Centre: Carrier housing with lenses and semi-transparent mirror.

Right: Rotating phosphor plate

Bottom: Reflective layer of barium sulphate

Incoherent light is emitted upwards.

The narrowest light beam achievable with the ORON® H2 is 0.6°.

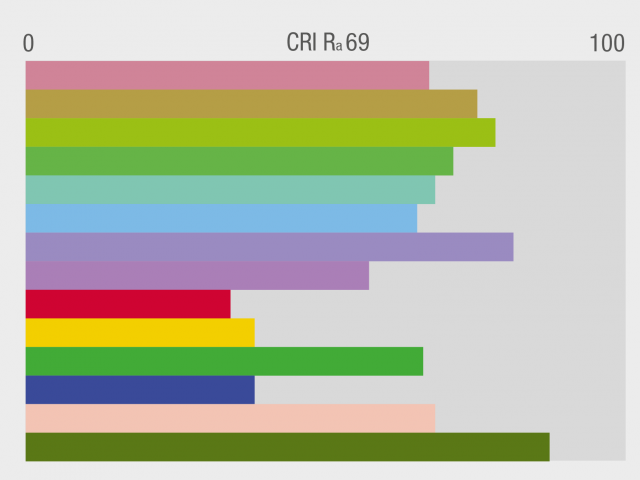

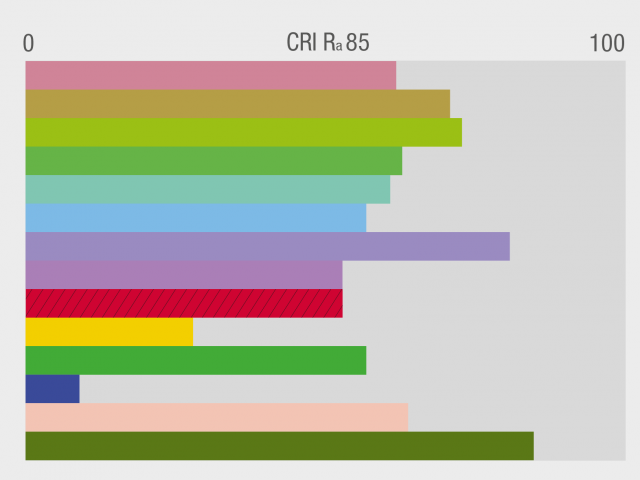

ORON® H2 with phosphor laser engine showing an extremely high and narrow peak in the blue.

Although blue reaches the highest value in the spectrum, the blue component for colour rendering is very small. The reason for this is that the reference colour is a different blue to the laser phosphor engine’s blue, which is very narrow-banded. The red is marked with hatched lines to highlight the negative sign.

This results in a very small and intense point light source, which is ideal for projected images or small beam angles for lights. The advantage is that you can dim the laser array just like you would an LED. Manufacturing this module, however, is very cost-intensive. Furthermore, the light is perceived as very bright due to the extreme blue peak. The colour gamut is also limited, as is the colour rendering quality. The cooling, service life, and the ON and OFF switching behaviour are similar to that of the LED.

Conclusion

As an all-rounder, the LED is the ideal light source for almost all types of lights. LEDs are replacing discharge lamps based solely on their good dimmability, colour gamut, and colour rendering or colour consistency over their service life. Not least due to their durability and robustness against vibrations. Only when very narrow beam angles are required can the discharge lamp score points. A beam lamp with extremely narrow beam behaviour is used for beam shows in which the light beam becomes a visible object. The colour gamut and colour rendering no longer play a role here, a clean line as a beam is what matters. If you want to create even more striking light beams in the sky or in a space, you can use the laser phosphor engine.

#CameoLight #ForLumenBeings #Lichtsources #EventTech #ExperienceEventTechnology

Further information:

cameolight.com

adamhall.com