Developing compact subwoofers

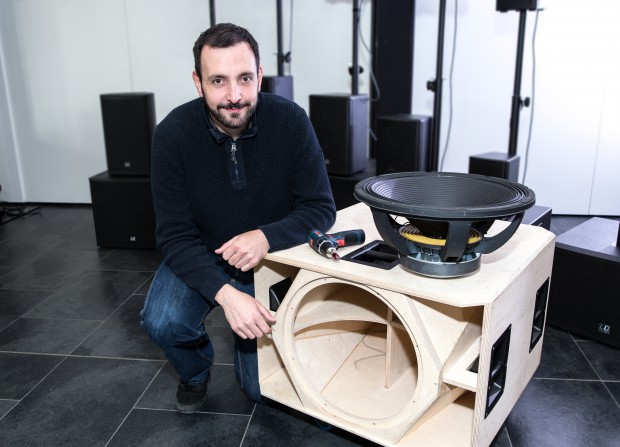

Graduate Engineer Martin Jung is Senior Acoustic Engineer at Adam Hall. He spoke with PRODUCTION PARTNER about the development process and system performance in the subwoofer sector.

Martin, LD Systems offers systems at smaller prices, but big is the term that you would normally attribute to bass. How do you go about achieving powerful bass reproduction?

Martin Jung: When developing cost-sensitive products, every detail has to be carefully optimised. The components used must be optimised to work well together. For each application, it is also necessary to strike the most suitable compromises in terms of enclosure size, output and frequency range. For example, with active bass systems it is important to match the minimum impedance, voice coil size and capacity of the chassis in the enclosure with the power amplifier in order to achieve optimum performance and operational safety. The enclosure must be constructed as rigidly as possible. If, for cost reasons, you can only use a few struts, then naturally these must be positioned optimally. In ventilated subwoofers, the bass reflex ports should not distort even at high levels. At the same time, heat must be dissipated from inside the enclosure. This can be achieved by the appropriate sizing, placement and design of the ports. By considering all of these factors, we at LD Systems are able to deliver extremely solid bass reproduction.

In recent years, which technical developments have made it easier for the R&D department to create powerful subwoofers?

Martin Jung: The introduction of numerical simulation (BEM/FEM) into the development process has significantly improved the quality of the speaker chassis and enclosures. This makes it possible to achieve better results with a given material and to optimise the components in the disciplines of electrodynamics, acoustics, mechanics, thermals and fluid mechanics. The worldwide prevalence of measurement technology (Klippel/WinMF) and the corresponding know-how in the area of development and quality assurance have led to a reduction of non-linear distortion and an improvement in chassis consistency. Improved amplifiers and optimised power supplies with PFC have increased enormously the power available for bass reproduction. The chassis suppliers have also improved the capacity of the chassis accordingly through the use of heat-resistant materials and adhesives, optimised ventilation and extended cone travel capacity.

To what extent can you as a developer influence the design and production of the chassis itself, and how does this affect performance?

Martin Jung: Chassis development is generally done in consultation with the chassis supplier. During of the development process, the drive factor/BL, minimum impedance, maximum load capacity, necessary linear diaphragm stroke and parts of the TSPs of the chassis are defined. With the available budget we can thus optimise and ensure efficiency and performance under any operating condition.

What approach would you recommend to someone wanting to compare subwoofers before choosing one?

Martin Jung: When comparing subwoofers, it is important to listen to them at exactly the same volume level and to correctly couple the bass acoustically to the mid or high-frequency speakers. The switchover process should be carried out immediately, and in order to remove any room influences, the comparison should ideally take place outdoors. When making a listening comparison, it makes sense to first listen to the bass at a medium volume level in order to perceive any tonal differences. The response in the upper limit area should then be compared with a variety of signals. In addition, the tests in PRODUCTION PARTNER provide a good technical reference point in order to gain an overview of the performance of the systems.

Handling, flexibility, durability and portability are of course also aspects to which we attach great importance, and which we optimise with extensive effort during the development process.

Graduate Engineer Martin Jung is Senior Acoustic Engineer at Adam Hall

https://www.production-partner.de/story/kompakte-subwoofer-entwerfen/